In this third part of our SIM83-TS01 truck simulator build, we focus on the heart of the system—its brain, the computer.

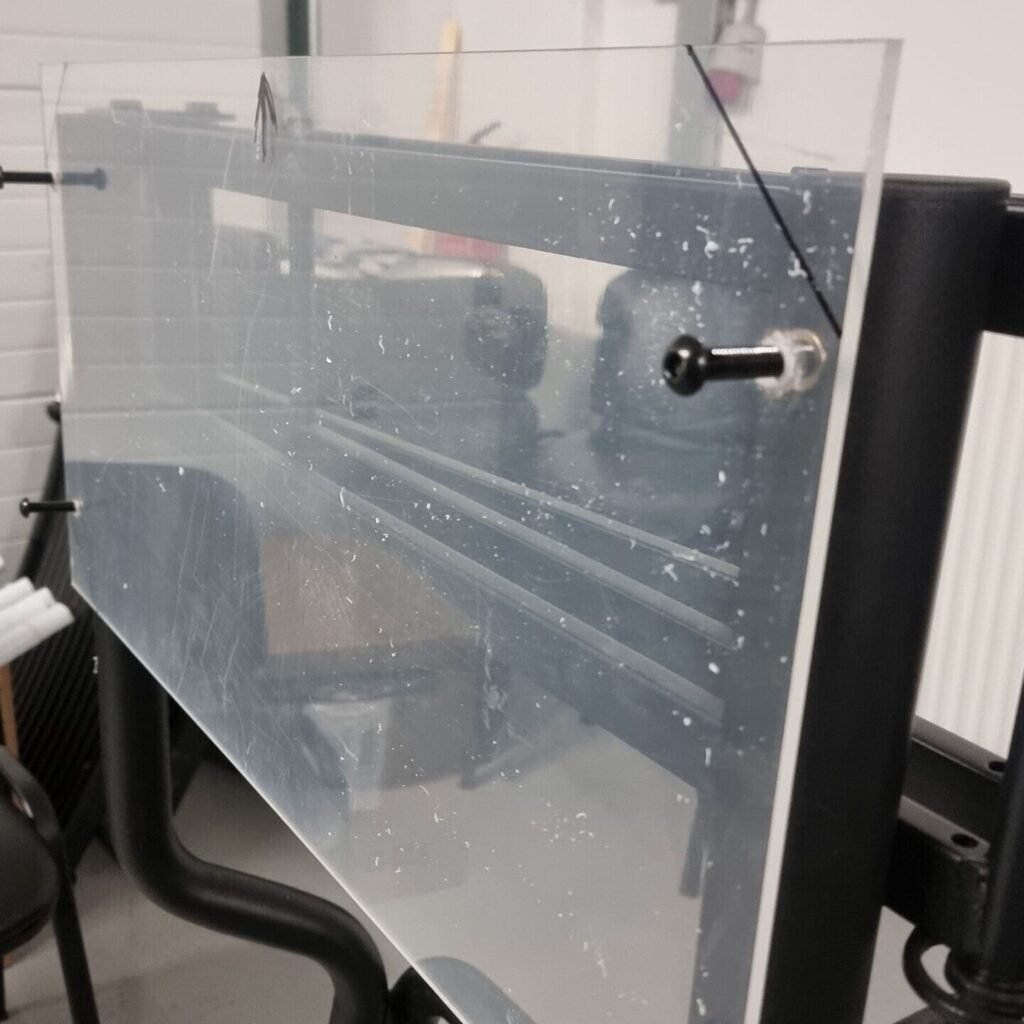

This isn’t your everyday PC setup. Instead of a standard case, all the components are mounted directly onto a transparent acrylic panel. This design choice is part of our mission to fully integrate every part of the simulator into a cohesive, functional, and visually striking unit.

We begin by laying out all the components and checking that everything is ready. Once confirmed, the components are arranged flat on a pre-cut acrylic panel, where we mark the positions for each mounting hole.

Drilling comes next—holes for securing the panel to the simulator frame, and others for mounting each component precisely. Some parts require minor modifications to be mounted securely, ensuring a clean and solid fit.

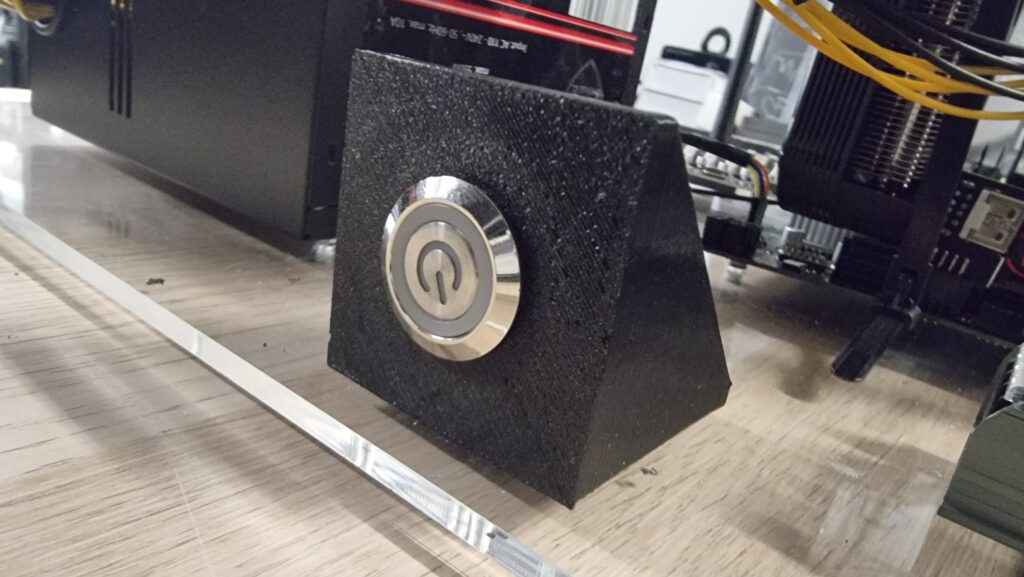

One unique element of this build is the custom power button and holder. These were specifically designed for the simulator and 3D printed in PETG by our partner Additio. This adds both functionality and a polished look to the final setup.

With the hardware in place, we do a bit of cable management to keep everything neat and tidy. Then it’s time for the software.

The system runs on Windows 11 Pro. In addition, we install software to control seat shakers, manage the force feedback steering wheel and pedals, and, of course, our simulation platform—eXpanSIM.

This integrated, open-concept build not only looks great but also keeps everything accessible for maintenance and upgrades—exactly what we aim for in professional-grade simulators.

Stay tuned for part 4, where we begin with our dashboard.